When was the last time you looked at a glass slide through a microscope? High school? College?

When was the last time you looked at a glass slide through a microscope? High school? College?

If it has been a while, you won’t be surprised to learn the process, like just about everything else, has gone entirely digital. You probably noticed if you’ve had an X-ray, blood drawn, an MRI, or some other medical test, the processing and results are computerized.

The last of the disciplines to join the digital age was pathology, which needed a higher resolution than radiology to identify individual cells. Up until just a few years ago, that technology was not available.

Now, it is.

It will take another five years before pathology goes digital in hospitals, but the change is happening more quickly in pharmaceutical and medical device research.

New higher resolution scanners, like the ones at Flagship Biosciences in Flagstaff, can process up to 600 samples a day, quickly and efficiently.

“We saw a real need for better usage of the technology in two areas, pharmaceutical drug development and in medical device development,” said Dr. Steve Potts, CEO of the company.

Important in these endeavors are clinical trials, and that is where Flagship can offer a broad range of tissue assessment options and tests of how a medical device, like a stent or graft, is working.

He said these studies determine if the drug or device is doing what the researcher or doctor wants it to do or if there are undesirable side effects.

Jokingly, he pointed toward drug ads on television that name a huge number of side effects.

“See how great this drug is on asthma, but by the way, it takes out your liver,” he said.

Flagship, which has been with the business incubator Northern Arizona Center for Entrepreneurship and Technology for about two years, provides quantitative tissue analysis services for pharmaceutical and medical device development.

Potts, 39, says he finds his work satisfying.

“It has a direct impact in cancer and diabetes and speeds the time to have a drug on the market. It can take a year off the trials for better, faster pathology,” he said.

Potts says it takes at least 12 years for a drug to make it to market, along with a billion dollar investment. For medical devices, it takes at least five or six years, with the size of investment “all over the map,” he said.

He says that for drugs, about 90 million slides worldwide per year need to be evaluated to detect changes in samples taken from test subjects. For medical devices, there are about 10 million.

Recently, Flagship is seeing increased security by the FDA for medical device manufacturers to show efficacy in their implanted devices, which generates work for the company.

“We were previously just running toxicity studies, which had been enough,“ he said.

The additional tests might help determine if a surface coating on a stent might have poor biocompatibility effects on local tissue, Potts says.

His clients come from the bay area in California, New Jersey, Boston, “wherever pharmaceutical technology centers are. We also work with local Arizona clients.”

The pathology can be done in Flagstaff and the results sent via computer to the client, which cuts time and costs for clients.

The company currently has 12 employees, including partners, but the team is far-flung.

“It’s the best team in the world because I don’t have geographic constraints.”

Potts recently added Holger Lange, Ph.D. from Germany. Lange was previously director of image analysis at Aperio. He is a leading expert in the use of image analysis in a regulated clinical environment.

“We have the best pathologists and image analysts working side-by-side, even if they are in other countries – and we have access to a great labor pool we are developing locally,” he said.

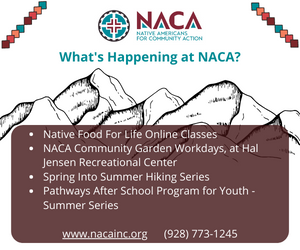

The company has been with NACET for two years and sales for the company has increased 400 percent since last year.

“Not only does NACET provide a great location, they give great business advice and world class connection marketing. Website development is a huge part of it,” Potts said.

NACET is glad to lend a hand.

“Clients like Flagship Bio Sciences are the types of clients we are looking for here at NACET,” said Jeff Saville, vice president of the incubator. “They have developed systems that make their industries much more efficient, giving them a competitive advantage in the marketplace. We see Flagship growing month after month and they are top-notch professionals and subject matter experts. They continually are hiring students from Northern Arizona University at a high wage, helping eliminate the brain drain here in Flagstaff.”

A native of Colorado, Potts lived all over the world because his father was a civilian Ph.D. working for the defense industry.

The moves were beneficial for him.

“The international part was helpful because I’ve always been very strong in the aspects of international business,” he said.

He did his undergraduate work in physics at Wheaton College in Illinois. He earned his MBA and doctorate at the same time at the University of California, Davis.

He originally taught biology at an international school in Switzerland.

Potts married his wife, Lisa, in 1995. The couple has two children who are five and nine.

They moved Northern Arizona two years ago.

“We did it for family reasons. We have family roots in Flagstaff,” he said.

He likes the year-around opportunity for sports in the area, like hiking and skiing. The family is active at Trinity Heights Methodist Church.

The future for the company is just to keep moving forward.

“We are expanding our capabilities in a number of new areas of cancer, diabetes and medical devices,” he said.

The company is also gaining an international reputation, with a number of clients in other countries. FBN